Flow around a ship’s hull is highly complex – which is one reason why the industry still doubts numerical approaches like CFD when it comes to predicting a vessel’s powering, seakeeping, and manoeuvring. By large, the industry still uses scaled model testing as the preferred option. Model testing has been around for more than a century and is a time-tested approach for Naval Architects. Whether the different CFD solvers and techniques have matured enough to replace model testing is a topic which is widely debated. While some CFD protagonists are upbeat about a future date when CFD will replace model tests completely, our present focus is to complement and supplement model testing, rather than replace it.

SEDS started investing in CFD in 2011-12, at a time when the expertise was largely limited to academics and subject matter experts in model basins, at least in the marine sector. What started as a time-filler for a rather powerful computer of the time (48 cores and 64 GB of RAM which had video rendering as its primary objective) soon became a thriller with encouraging predictions of powering performance for in-house designs.

Any non-linear numerical analysis is incomplete unless validated against experimental results. The usual approach is work with what is available in the public domain – the Duisburg Test Case, David Taylor Model Basin (DTMB 5415 – Naval combatant), Kriso Container Ship (KCS), Kriso VLCC etc. are some of the model-tested hull geometries with resistance/propulsion results available in the open literature. However, most of these hulls were never tested at sea, and there is no benchmark to compare the experience-based correlation allowances used in model basins or the accuracy of tests conducted at different model test facilities.

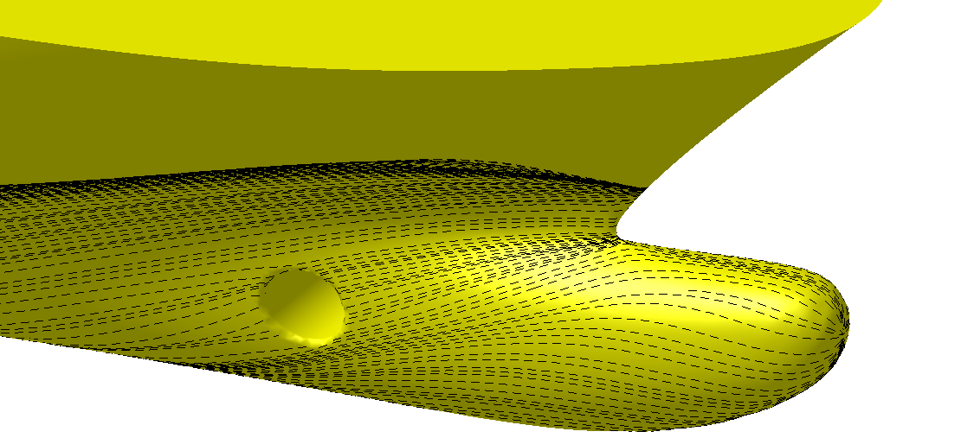

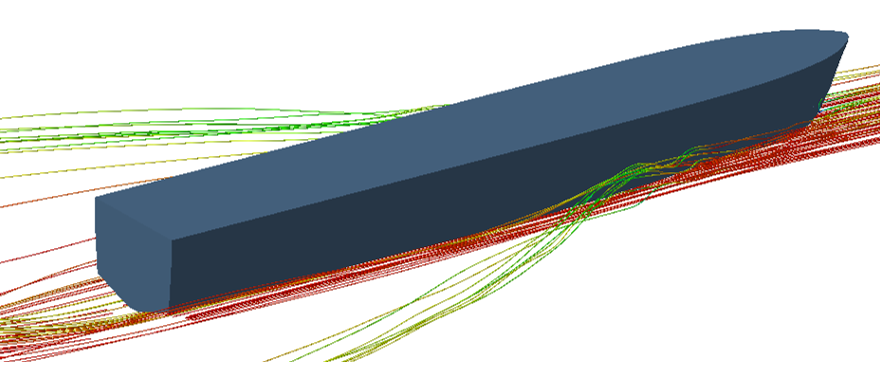

SEDS had a real advantage here – a huge database of ships built to its design, complete with model test and sea trial data, a treasure trove for any marine CFD analyst. From slow speed bulk carriers with low Froude numbers to medium speed large passenger vessels and catamaran ferries to high-speed Naval combatants and very high speed and high Froude number water-jet propelled patrol vessels – name it. The techniques employed to capture the performance of a slow-speed displacement mode cargo freighter is quite different from that of a high-speed semi-planing chined hull with waterjet propulsion. Our team successfully validated different hull forms, propellers and Energy Saving Devices, and matched the performance with model test and sea trial results. Streamlines from a displacement mode sub 20 knots speed passenger vessel and a high-speed semi-planing vessel jet Fast Patrol Vessel at 30+ knots are shown in the figure below.

Figure 1: Simulation of a displacement mode vessel and a semi-planing vessel

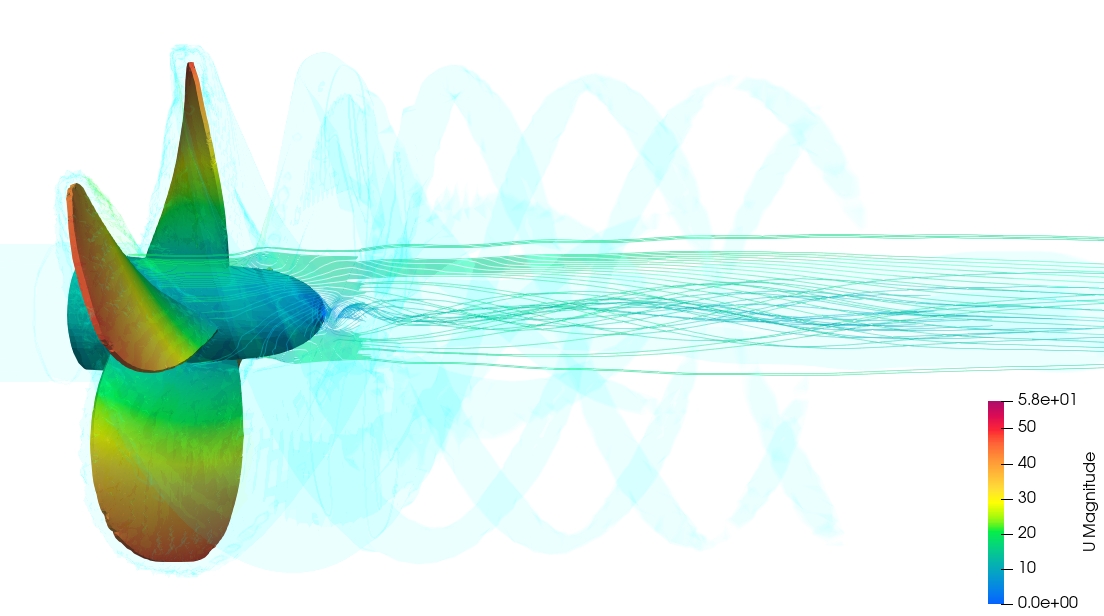

Going deeper into the technicalities – a CFD analyst needs to have a clear understanding of steady/unsteady flow, turbulence models, level of discretization needed, right element types, appropriate solvers, solution convergence, boundary layer thickness, moving reference frame/overset mesh definition and so on – topics which are best handled by subject matter experts. The figure below shows a propeller open water simulation.

Figure 2: Propeller vorticity contour- Velocity plot with stream tracer

By 2019-2020, SEDS developed a full-fledged CFD team with expertise in open-source and commercial CFD packages. Today, the team is engaged in the design of Energy Saving Devices (ESDs), evaluation of renewable energy concepts, design of high efficiency hull forms, silent propellers for defence applications, plume trajectory analysis, ventilation/exhaust flow simulations etc.

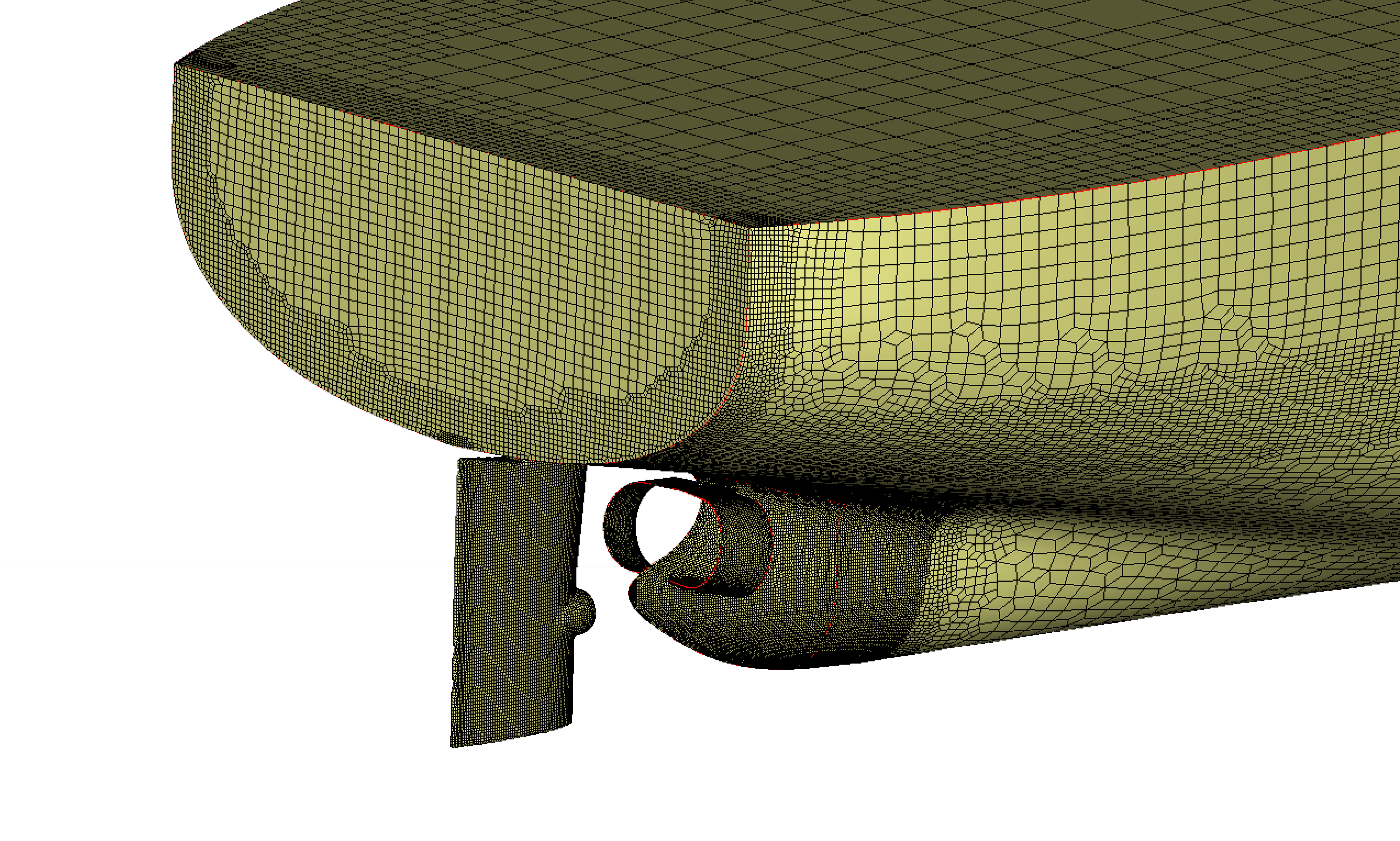

With the shipping industry poised to deliver big in its journey towards decarbonization, SEDS is leading the way by helping owners implement energy saving solutions, embrace renewables, and optimize their operation profiles. The CFD team plays an important role in this effort by helping owners to meet EEXI/CCI targets by optimizing trim, selecting the right pre-swirl or post-swirl flow improvement devices – like wake equalizing ducts, boss cap fins etc., propeller and hull modifications to suit engine power limitations and so on. SEDS has already discussed and agreed on the approaches to be followed for specific energy saving devices with all major classification societies such that the turnaround times can be minimized.

Figure 3: Wake Equalizing Duct design and CFD verification

Figure 3: Wake Equalizing Duct design and CFD verification

The CFD team is part of a larger Advanced Analysis division in SEDS which works on explicit dynamics, multi-physics, electromagnetics, and acoustics. This helps the team to handle multi-disciplinary and multi-phase problems like fluid-structure interaction, hydro/aero-elasticity, vortex-shedding, fluid mixing and turbidity, fluid flow with heat transfer among other complex fluid simulations – and serve a diverse industry profile. This shall be covered in a separate article.

What started with two young engineers experimenting on a simple 2-dimensional dam-break simulation about 10 years ago has matured into an expert group who can provide total solutions to customers in advanced flow problems. If you are looking for the right partner who walks with you in understanding and solving your performance issues and helps in achieving efficiency/ decarbonization goals, then look no further.

We typically get the following queries from ship Owners:

- Can you confirm if the efficiency gain promised by an Energy Saving Device manufacturer can be achieved?

- Can you suggest the best combination of solutions to achieve EEXI/CII targets?

- Do you have experience with the major model tanks like MARIN, HSVA, SVA etc.? Can you help us in discussing with them?

- Do you have experience with alternate fuels? Can you help us with retrofitting a new technology?

- Can you check why the vessel is under-performing?

The one answer that we have for all the above queries is a big “YES”. We will help you!

SEDS CFD TEAM